The Benefits of Air Sentry Breathers

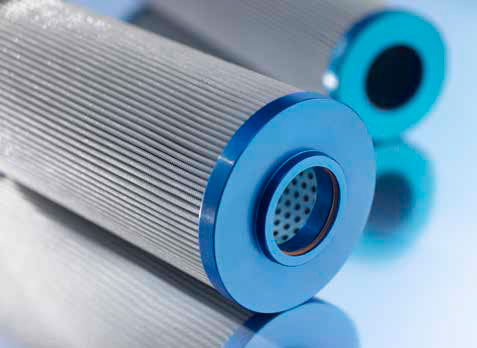

Contamination control breathers (such as Air Sentry breathers) can help you achieve near-total control of fluid system contamination. They are designed to replace the breather cap or air filter on gear boxes, hydraulic fluid reservoirs, bulk storage tanks, oil drums, oil-filled transformers and other fluid reservoirs. They absorb water from the air before it enters your fluid system, and can remove particulate contaminants as small as two microns. The visible silica gel found in a contamination control breather changes color as it becomes depleted, so it’s easy to identify the condition of one and quickly replace it if needed.

Air Sentry breathers include four layers of protection: two solid contaminant filters, a layer of high-capacity water vapor absorption media, and an activated carbon filter. A two-way system (the bi-directional movement of airflow) allows expelled air to black-flush, thus extending the life of the air breather.

When contaminated air enters the top of an Air Sentry breather, it passes through the upper solid contaminant filter. This keeps solid contaminants from entering the breather and depositing on critical surfaces. The filtered air then passes through a bed of silica gel that absorbs moisture from the air. It is during this process that up to 90% of the water vapor in the air is filtered out (thus preventing oil vapors, fumes and odor). Then, the filtered air passes through another filter at the bottom of the breather to ensure that no harmful particles will enter the tank or reservoir. This means that equipment is ensured to get clean and dry air.

As air is expelled from the reservoir through the desiccant breather, the contaminated air travels this reverse path, and expelled water vapors are absorbed by the silica gel. When the silica gel has absorbed to full capacity (indicating that it is time to remove and replace the disposable breather), the gel will turn from gold to dark green.

Additionally, a layer of activated carbon lies at the bottom of our Air Sentry breathers. This carbon pad absorbs small amounts of oil vapor exhaled from the tank, thus protecting the silica gel from oil mist contamination.