Two common types of compressed air dryers are refrigerated and desiccant. It is important to learn from a reputable compressor air filter supplier in Richmond how each drying technology works to learn which is best for your application.

Two common types of compressed air dryers are refrigerated and desiccant. It is important to learn from a reputable compressor air filter supplier in Richmond how each drying technology works to learn which is best for your application.

Refrigerated dryers

Refrigerated dryers work by cooling the air to low temperatures and condensing much of the water vapor. It is not possible to achieve dew points below freezing with a refrigerated dryer. Refrigerated dryers that are optimally designed can produce air with dew points to approximately 36°F (2°C). Since some water vapor is left in the air, these dryers should not be used in applications that are water sensitive.

Desiccant dryers

On the other hand, desiccant dryers operate by passing the compressed air over a bed of desiccant material which absorbs water vapor molecules. When the bed capacity is nearly saturated, the air flow switches to a second bed of desiccant material. The first bed is then regenerated. Desiccant air dryers can deliver air at consistently low dew points. This technology is an excellent choice when the compressed air is subject to freezing conditions. While heated desiccant dryers use heat to remove water vapor from the desiccant material not in use at that point in the cycle, heatless dryers use the dry air to remove water vapor from the desiccant material.

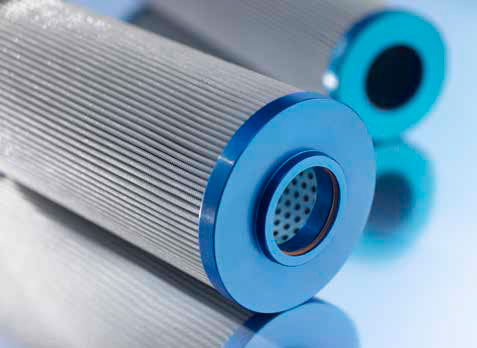

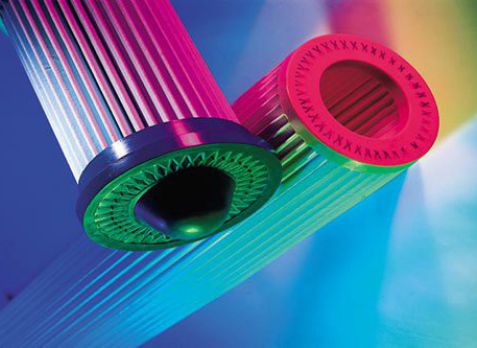

Greenleaf Filtration offers a wide array of liquid bag filters for the unique needs of your facility. With a wide range of micron sizes, our inventory of bag filters can support many industries, such as chemical, food, and paper. Keep reading for some information on three popular types of liquid filter bags from our

Greenleaf Filtration offers a wide array of liquid bag filters for the unique needs of your facility. With a wide range of micron sizes, our inventory of bag filters can support many industries, such as chemical, food, and paper. Keep reading for some information on three popular types of liquid filter bags from our  Scale deposition commonly occurs in all pulp and paper-making processes. Even with the purest water treatment, scale deposits can cause an array of operational issues, such as increased utility costs and lost production due to downtime. The following are just a few of the processes affected by scale formation.

Scale deposition commonly occurs in all pulp and paper-making processes. Even with the purest water treatment, scale deposits can cause an array of operational issues, such as increased utility costs and lost production due to downtime. The following are just a few of the processes affected by scale formation. Did you know that dirty and clogged air filters are the main cause of heating and cooling system problems?

Did you know that dirty and clogged air filters are the main cause of heating and cooling system problems? At Greenleaf Filtration, our products touch the lives of our consumers in positive ways every day. We supply a unique inventory of industrial filtration products, including

At Greenleaf Filtration, our products touch the lives of our consumers in positive ways every day. We supply a unique inventory of industrial filtration products, including  Over time, the presence of scale deposits can affect the efficiency of equipment such as air compressors, heat exchangers, vacuum pumps, boilers, and cooling towers. Sublime Water Scale Solvent is available to return scaled processing equipment to top operating efficiency.

Over time, the presence of scale deposits can affect the efficiency of equipment such as air compressors, heat exchangers, vacuum pumps, boilers, and cooling towers. Sublime Water Scale Solvent is available to return scaled processing equipment to top operating efficiency. No business owner wants to spend more money on equipment and resources than they have to, and this doesn’t exclude owners of hydraulic systems and equipment. This begs the question: how can you make your hydraulic oil go further and last longer? The following are three things that efficient hydraulic oil supplies have in common.

No business owner wants to spend more money on equipment and resources than they have to, and this doesn’t exclude owners of hydraulic systems and equipment. This begs the question: how can you make your hydraulic oil go further and last longer? The following are three things that efficient hydraulic oil supplies have in common. Every home or business owner wants an HVAC unit that operates properly and keeps their home or office at the right temperature. However, most people also want a system that can do the job properly without burning a hole in their pocket. To ensure a system that works efficiently, here are some things to look out for that could be bad for your heating and cooling unit.

Every home or business owner wants an HVAC unit that operates properly and keeps their home or office at the right temperature. However, most people also want a system that can do the job properly without burning a hole in their pocket. To ensure a system that works efficiently, here are some things to look out for that could be bad for your heating and cooling unit. Compressed air systems represent about one-tenth of the total energy a manufacturing plant consumes. Here are some strategies to pursue for improving compressed air system efficiency without undergoing a full system replacement.

Compressed air systems represent about one-tenth of the total energy a manufacturing plant consumes. Here are some strategies to pursue for improving compressed air system efficiency without undergoing a full system replacement. Aside from human error, the most common source of hydraulic system failure is fluid contamination. In fact, it is estimated that up to 90% of hydraulic failures result from contaminated fluids. Contamination can exist as solid particles, water, air and reactive chemicals – all which can negatively affect fluid functions in one way or another. If any of these functions are debilitated, the system will not perform as it should, and sudden, catastrophic failures become possible. The repairs needed and resulting downtime can easily cost a facility thousands of dollars.

Aside from human error, the most common source of hydraulic system failure is fluid contamination. In fact, it is estimated that up to 90% of hydraulic failures result from contaminated fluids. Contamination can exist as solid particles, water, air and reactive chemicals – all which can negatively affect fluid functions in one way or another. If any of these functions are debilitated, the system will not perform as it should, and sudden, catastrophic failures become possible. The repairs needed and resulting downtime can easily cost a facility thousands of dollars.